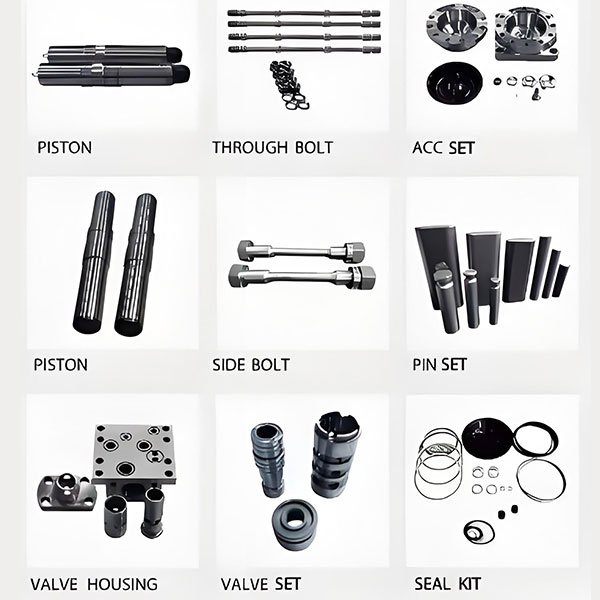

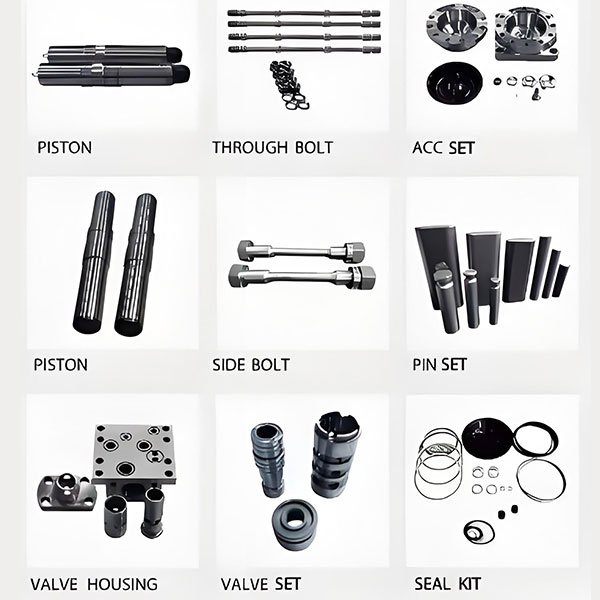

Hydraulic Breaker Spare Parts Description

- Through bolts : Longer service life by to applied heat treatment.

- Back head: Material: 20CrMo, impact energy is accumulated due to charged nitrogen gas in the block.

- Front Head: Using 20CrMo material, high quality with long life using.

- Valve: We adopt production process by grinding machine, with high precision.

- Cylinder body: Material: 20CrMo, it is best quality material.

- Piston: Longer service life by optimized design and high quality special steel.

- Front Head: Using 20CrMo raw material, which are provided by domestic famous manufacturer, forging again and again to make internal organization more tight and increasing the Hydraulic breaker wear-resistance.

- Chisel: The specially heat treated chisel is directly applied to break rocks. There are four types for choosing: Moil, Blunt,

- Flat, Conical Point. The material is 42Crmo.

- Main Body: Including Front head, cylinder and back head. Ensure your breaker will be in best performance

- Seal Kit: We can supply both Parker and NOK seal kit which are most famous brand in the business line.

YLB1400/SB81 Model Technical Data

| 1 | Operating Weight | 1720 | kgs |

| 2 | Required Oil Flow | 130-170 | L/min |

| 3 | Working Pressure | 190-220 | bar |

| 4 | Impact Rate | 350-500 | bpm |

| 5 | Hose Diameter | 1 | inch |

| 6 | Tool Diameter | 140 | mm |

| 7 | Excavator Weight | 20-26 | ton |

Hydraulic Breaker Spare Parts Applications

Hydraulic Breaker Spare Parts – Precision Solutions for Specialized Applications

Unlike generic spare parts, our genuine components excel where standard parts fail:

1. Extreme Cold Mining Operations (-40°C)

▶️ Special low-temp seals prevent brittle fractures

▶️ Arctic-grade hydraulic fluids included in service kits

2. Underwater Demolition Work

▶️ Triple-coated corrosion-resistant pistons (saltwater proof)

▶️ Pressure-balanced accumulators for deep-water use

3. Tunneling & Underground Projects

▶️ Compact retrofit kits for confined space breakers

▶️ Dust-proof valve systems with 3-stage filtration

4. High-Frequency Quarry Operations

▶️ Forged tungsten striker tips (2.5x standard life)

▶️ Vibration-dampening bushings reduce metal fatigue

5. Recycling Plant Demolition

▶️ Reinforced front heads for rebar penetration

▶️ Magnetic seal kits contain metal碎片

Technical Edge:

- Material-Specific Solutions: Different alloys for granite vs concrete

- Smart Parts: RFID-tagged components for usage tracking

- Emergency Kits: Pre-packed for common failure scenarios

Why Our Spare Parts Outperform:

✓ Precision-matched to OEM breaker specifications

✓ Environment-optimized versions available

✓ Real-world tested in 50+ mine sites globally

(Custom engineering available | Express shipping for urgent breakdowns)

Production Process Video Of Hydraulic Breaker

Hydraulic Breaker Spare Parts Detail Display

Related Products

Related News

Pterosaur YLB-1400 silent breaker hammer is put into use Customer review