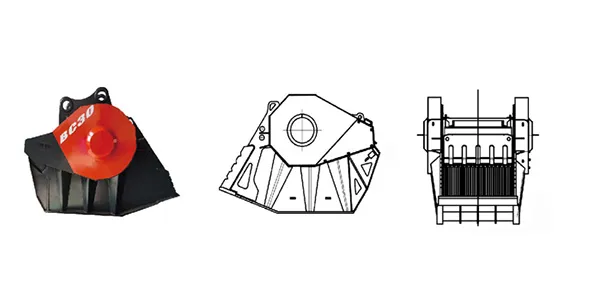

Excavator Crusher Bucket

Excavator Crusher Buckets transform rocks to rubble on-site with hardened steel jaws.Baicai delivers demolition solutions featuring hydraulic adjustment and 360° operation.

Excavator Crusher Bucket – Key Features & Benefits

✔ Hardened Steel Jaws – High manganese steel construction for crushing rocks/concrete with 20-25% longer wear life vs standard models

✔ On-Site Material Processing – Eliminates hauling costs by crushing debris directly at demolition/construction sites

✔ Hydraulic Adjustment System – Precise control of output size (20-120mm) for recycling/landscaping applications

✔ 360° Rotation Compatibility – Works with excavator’s slew ring for multi-directional crushing without machine repositioning

✔ B2B-Grade Durability – Reinforced frame and replaceable wear parts reduce downtime for contractors/quarry operators

✔ Direct Hydraulic Connection – No external power needed; runs on standard excavator hydraulic circuits

Excavator Crusher Bucket Description

Professional Excavator Crusher Buckets for On-Site Material Reduction

With the excavator as the power source,construction can be carried out anytime and anywhere, which is convenient and efficient.Hydraulic motor and valve of the joint venture brand the main parts of the bucket body use imported wear-resistant plates and domestic high-strength plates.Jaw plate is high-strength and wear-resistant and both ends of the jaw plate can be used.

As a premier manufacturer and global supplier of excavator crusher buckets, we deliver heavy-duty crushing attachments that transform job site waste into reusable material. Our hydraulic crusher buckets feature hardened steel jaws with adjustable output (20-120mm), perfect for demolition, quarrying, and land clearing. Designed for 3-45 ton excavators, these B2B-grade attachments eliminate off-site crushing costs while improving recycling efficiency. Trusted by construction firms, demolition contractors, and aggregate producers, our rotary crusher buckets offer 360° operation and quick-wear part replacement. Bulk order discounts available – request your quote today to cut material processing costs!

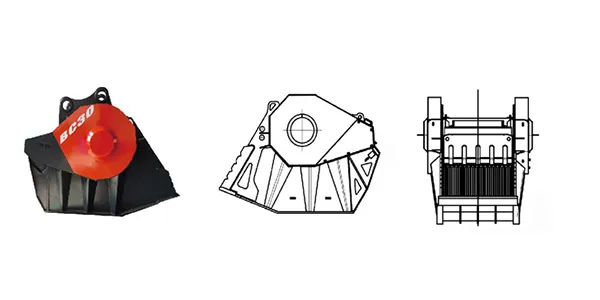

Excavator Crusher Bucket Technical Data Sheet

| Model | BC20 | BC30 | BC40 |

|---|---|---|---|

| Suitable excavator [ton] | ≥20 | ≥30 | ≥45 |

| Weight [ton] | 3.15 | 4.75 | 7.59 |

| Dipper Capacity [m²] | 0.8 | 1.3 | 2.0 |

| Working Pressure [Mpa] | 24 | 24 | 28 |

| Oil Flow [L/min] | 220 | 240 | 300 |

| Opening Width [mm] | 850 | 1190 | 1300 |

| Opening Height | 430 | 525 | 474 |

| Overall dimensions | 2070×1310×1395 | 2150×1655×1385 | 2940×2080×1480 |

Excavator Crusher Bucket Applications

Excavator Crusher Buckets – Specialized Applications

Unlike standard crushing equipment, our Excavator Crusher Buckets solve unique challenges across industries:

1. Urban Demolition

360° rotation crushes concrete in tight spaces (e.g., basements/alleyways) where fixed crushers can’t operate

Low-noise processing meets city noise ordinances

2. Mine Rehabilitation

On-site overburden crushing converts waste rock into usable road base material

Adjustable jaw settings handle varied geological compositions

3. Disaster Cleanup

Direct debris processing at hurricane/earthquake sites bypasses overloaded landfills

Magnet-ready models separate rebar from concrete instantly

4. Quarry Pre-Screening

Primary crushing at extraction points reduces haulage of non-valuable material

Integrated grizzly bars (optional) pre-filter oversized rocks

5. Specialty Recycling

Brick-to-gravel conversion for historic building renovations

Asphalt pulverizing without removing steel mesh layers

Excavator Crusher Bucket Detail Display

More Information

Crusher bucket can push out the concrete or rock stuck in it through reverse rotation, and can also make the hydraulic motor rotate forward to continue crushing,which greatly improves the work efficiency.The upper and lower jaw plates can be exchanged for use, and the front and rear of a single jaw plate can also be replaced, greatly extending the service life. it adopts the independent and independent design of the hydraulic motor direct drive mode, which is easier to maintain.

Related Products

Related News

As a leading manufacturer of hydraulic breakers (also known as hammer breakers or rock breakers), we understand how frustrating it […]

Yes, mini excavators are often worth it. They offer versatility, easy maneuverability in tight spaces, lower operational costs, and are […]

Pterosaur YLB-1400 silent breaker hammer is put into use Customer review

The hydraulic breaker has arrived Customer review CE Certificate

The hydraulic breaker has arrived Customer review Related purchased products

Hydraulic hammers, also known as hydraulic breakers, are powerful tools used in construction, demolition, and mining. These robust attachments rely on […]

The first step in preparing the hammer requires attaching the Chisel. Operators connect the hammer to the excavator or other equipment […]

When purchasing a hydraulic breaker for a 20-ton excavator, understanding the price factors is crucial for making a cost-effective decision. The price […]