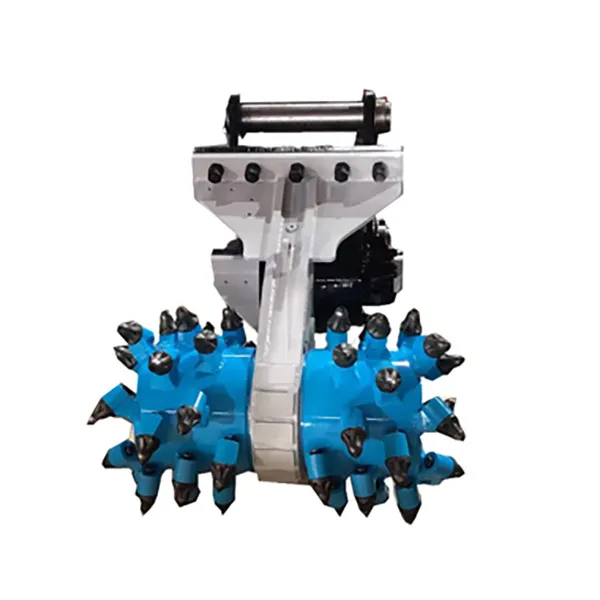

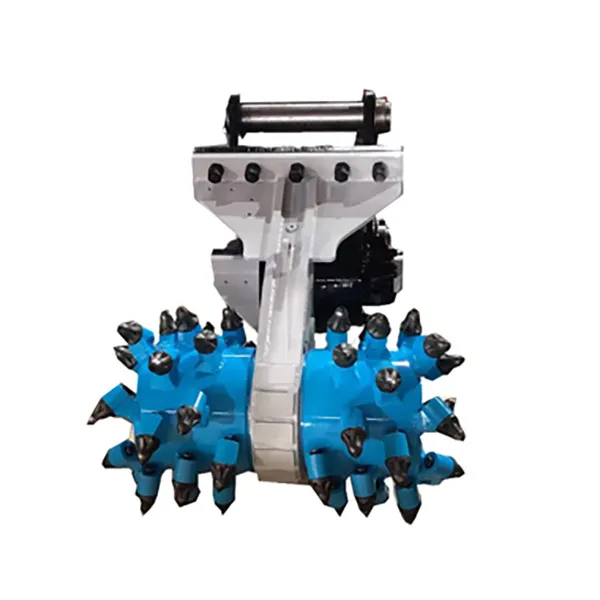

Hydraulic Drum Cutter Excavator Attachments

Hydraulic Drum Cutter are produced with high-strength steel and applications are demolition, tunneling, mining. Baicai manufacturer provide durable, high-performance solutions with global certifications.

Hydraulic Drum Cutter – Key Features & Advantages

High-Performance Cutting – Equipped with high-strength steel teeth for efficient demolition, rock breaking, and concrete cutting.

Durable Construction – Robust design ensures longevity and low maintenance, even in harsh environments like mining and tunneling.

Hydraulic Power Efficiency – Provides smooth, high-torque operation with minimal vibration for precision cutting.

Versatile Applications – Ideal for demolition, underwater work, road milling, and trenching across multiple industries.

Global Certifications – Complies with international safety & quality standards, ensuring reliability for B2B buyers.

Hydraulic Drum Cutter Description

Hydraulic Drum Cutter – High-Efficiency Demolition & Cutting Solution

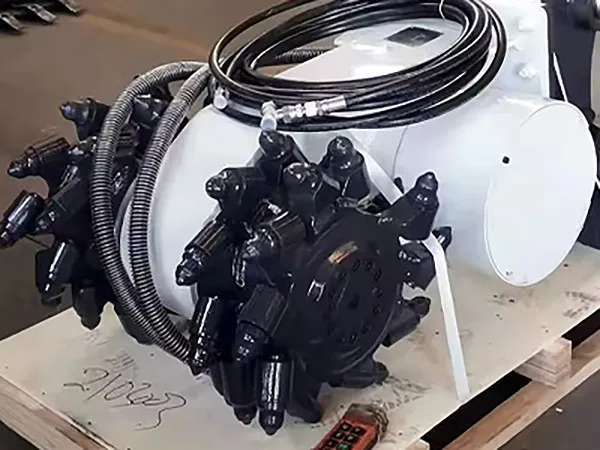

As a leading Hydraulic Drum Cutter manufacturer, we supply robust cutters designed for demolition, mining, and tunneling. Featuring high-strength steel teeth and hydraulic power systems, our cutters deliver precise, low-vibration performance in tough conditions. Available in multiple sizes (300mm–1500mm diameter), they efficiently handle concrete, rock, and reinforced structures. Ideal for construction firms, demolition contractors, and mining companies, our cutters reduce downtime and boost productivity. Choose a reliable supplier for durable, CE-certified solutions. Bulk orders welcome – contact us for competitive pricing!

Key Benefits:

✔ High cutting efficiency – Saves time & labor costs

✔ Low maintenance – Durable construction for long-term use

✔ Versatile applications – From underwater demolition to road milling

Hydraulic Drum Cutter Technical

| Model | BC140 | BC160 | BC180 | BC210 | BC240 | BC280 | BC350 | BC400 |

| Carrier tonnage(T) | 5-10 | 10-15 | 15-21 | 22-26 | 20-24 | 22-30 | 30-40 | 50-70 |

| Input Power(KW) | 22 | 45 | 55 | 80 | 65 | 70 | 110 | 200 |

| Max Pressure(Мра) | 400 | |||||||

| Recommend Flow (L/min) | 40 | 100-110 | 100-140 | 130-180 | 160-190 | 200-250 | 250-320 | 350-450 |

| Speed(r/min) | 0-120 | 0-100 | 0-80 | 0-80 | 0-90 | 0-70 | 0-60 | 0-60 |

| Max Picks Force (KN) | 18 | 28 | 43.5 | 48 | 50 | 52 | 68 | 128 |

| Max Torque(Nm) | 3200 | 5400 | 5600 | 9000 | 12800 | 14000 | 23500 | 47000 |

| Number of Teeth (No.) | 36 | 42 | 44 | 44 | 46 | 56 | 44-56 | 44-56 |

Get Free Quote of Hydraulic Drum Cutter

Precision cutting? Get your solution now!

Hydraulic Drum Cutter Applications

Hydraulic Drum Cutter – Specialized Applications for Challenging Environments

Unlike standard cutting tools, our Hydraulic Drum Cutter excels in precision demolition and material processing where power, control, and durability are critical.

Here’s where it outperforms alternatives:

1. Underwater Demolition (Marine & Offshore) Unique Advantage: Sealed hydraulic system resists corrosion, enabling deep-sea pile cutting and shipwreck dismantling where traditional tools fail.

Solved Problem: Eliminates the need for dry-docking, reducing project costs by 30%+.

2. Confined-Space Tunneling (Metro & Subterranean) Unique Advantage: Compact, low-vibration design allows safe use in narrow tunnels without structural damage.

Solved Problem: Enables selective concrete removal around rebar, preventing costly collapses.

3. Hard Rock Mining & Quarrying Unique Advantage: Tungsten-carbide teeth crush granite/basalt 3x faster than hydraulic breakers.

Solved Problem: Reduces drill-and-blast cycles, minimizing flyrock hazards.

4. Nuclear Facility Decommissioning Unique Advantage: Remote-operated models cut irradiated concrete with zero operator exposure.

Solved Problem: Meets IAEA safety protocols for radioactive containment.

5. Urban Demolition (High-Rise & Bridges) Unique Advantage: Dust-suppression compatibility meets EPA Tier 4 standards for city-center projects.

Solved Problem: Avoids work stoppages from noise/dust complaints.

Why Our Cutter?

✔ Patent-pending tooth geometry – 20% longer lifespan vs competitors

✔ Custom diameter options (400mm–2m) – Tailored for niche applications

✔ Global projects completed – From offshore wind farms to subway expansions

Hydraulic Drum Cutter For Excavator Video

55 Gallon Drum Cutter Hydraulic Drum Cutter Excavator Attachments Detail Display

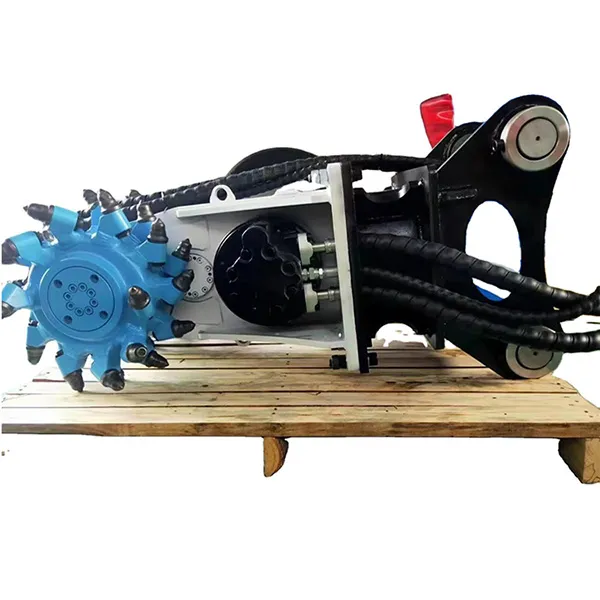

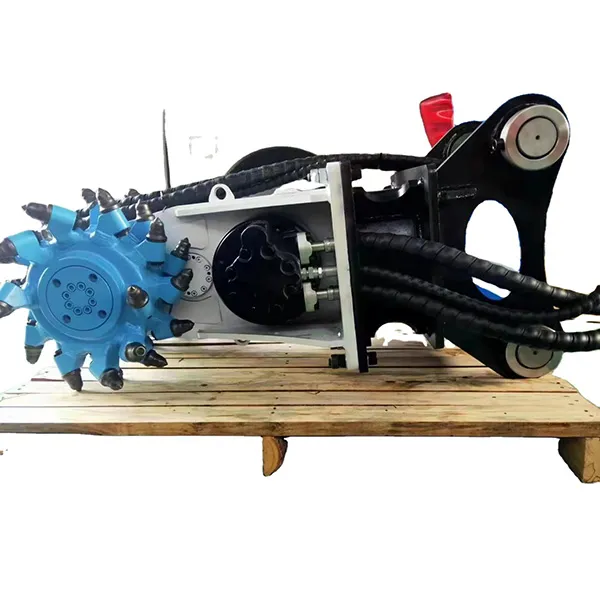

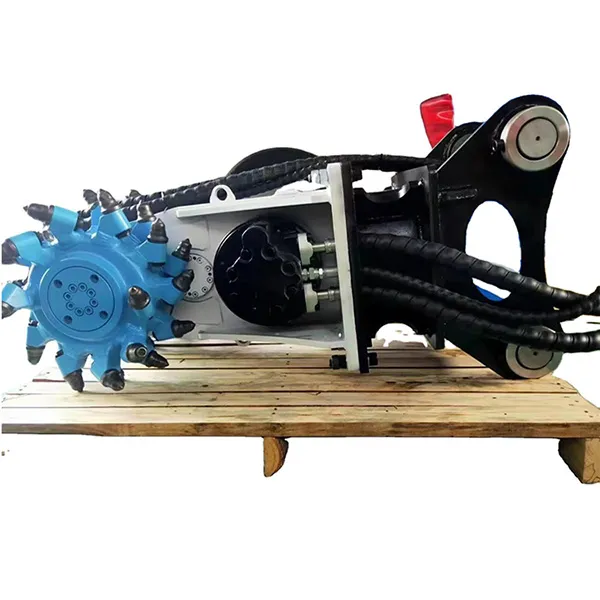

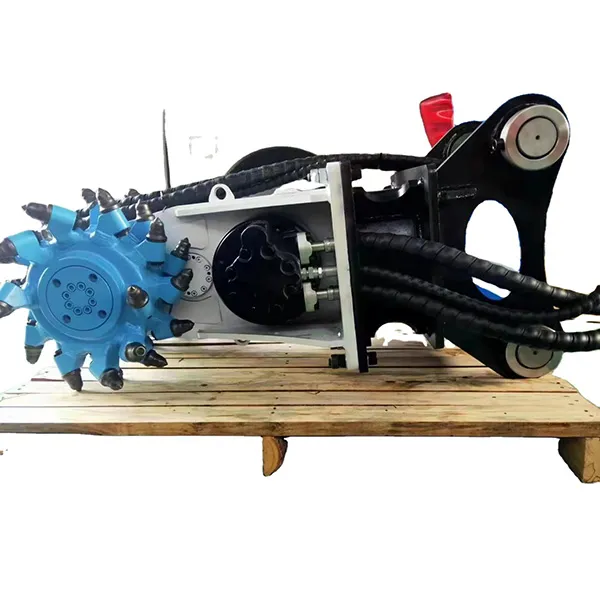

Standard Accessories

- Hydraulic Oil Hoses*2pcs

- Overflow Pipe*1set

- Tool Box with necessary maintenance tools*1set

Packing

- Inner is stretch film

- Outside is export wooden case

More Information

Excavator milling drum cutter machine can be installed on any type of hydraulic excavator, efficient replacement of bucket, crushing hammer, hydraulic shear and other general configuration, widely used in tunnel, ditch, municipal pipeline excavation, road surface crushing, mining, rock frozen soil excavation; Open pit coal mine excavation, surface renewal and iron and steel industry, forestry and other construction fields.

Different Configuration Different Cost. contact us for Details and Final Cost.

Related Products

Related News

As a leading manufacturer of hydraulic breakers (also known as hammer breakers or rock breakers), we understand how frustrating it […]

Yes, mini excavators are often worth it. They offer versatility, easy maneuverability in tight spaces, lower operational costs, and are […]

Pterosaur YLB-1400 silent breaker hammer is put into use Customer review

The hydraulic breaker has arrived Customer review CE Certificate

The hydraulic breaker has arrived Customer review Related purchased products

Hydraulic hammers, also known as hydraulic breakers, are powerful tools used in construction, demolition, and mining. These robust attachments rely on […]

The first step in preparing the hammer requires attaching the Chisel. Operators connect the hammer to the excavator or other equipment […]

When purchasing a hydraulic breaker for a 20-ton excavator, understanding the price factors is crucial for making a cost-effective decision. The price […]